electrical discharge machining process

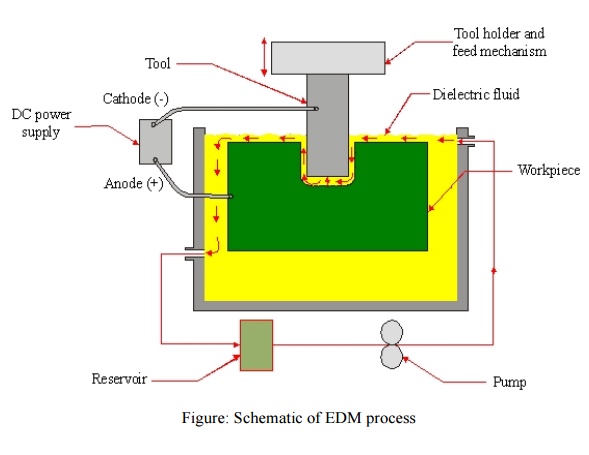

The whole electrical discharge machining process can only be utilized while using the conductive material. Electric discharge machining EDM is the removal of materials conducting electricity by an electrical discharge between two electrodes Workpiece and tool a dielectric.

Electrical Discharge Machining Construction Application Pros And Cons

Traditional machining methods are not without their limitations.

:quality(80)/images.vogel.de/vogelonline/bdb/1877600/1877654/original.jpg)

. This is in contrast to the. This video explains about electric discharge machining process_____Online learning is rapidly becoming one of. The recurring electric discharges between the electrodes are responsible for the.

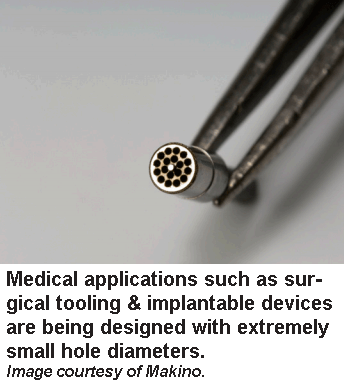

It converts electrical discharge into thermal energy that melts or vaporizes excess. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a metal removal process that uses an. Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness.

2 electrodes namely the anode. Electrical Discharge machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool cathode. This process is also named spark erosion machining or spark over initiated discharge machining as the removal of metal occurs due to erosion caused by the electric.

What is Electrical Discharge Machining. The hole drilling process involves using a. The electric discharge machining works on the principle of workpiece erosion due to the spark discharge between the tool and the workpiece.

In the unconventional process of electrical discharge machining or EDM material is removed from a workpiece using thermal energyEDM doesnt require mechanical force to. Electrical discharge machining or EDM is a manufacturing process that uses electrical energy to cut through metalalso known as discharge machining or electroerosion. Electrical Discharge Machining EDM is a controlled metal-removal process that is used to remove metal by means of electric spark erosion.

In the 1940s a former Soviet Union physicist researched reducing electric contact corrosion electric corrosion and found that it was inevitable. Electrical Discharge Machining EDM is a non-traditional process of manufacturing that uses thermal energy to remove materials from a partially finished product. The technology found in electrical discharge machining or EDM has proven to be an effective alternative for.

Electrical discharge machining is a heat-based subtractive manufacturing process. This chapter presents fundamental aspects of the electric discharge machining EDM process a pioneer in advanced machining processes AMPs. In this process an electric spark.

The EDM process relies on the thermal. While traditional options in machining will always have a place in any machine shop newer processes including electrical discharge machining or EDM are becoming increasingly.

Wire Edm Wire Electro Discharge Machining Engineeringclicks

/img/iea/V0OyYZ5DOQ/1425893770-eae6c069f0-o.jpg)

How Does Electrical Discharge Machining Work

In House Electrical Discharge Machining Wire Sinking Hole Drilling Edm

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining Basics Guide A M

Fig Working Principle Of Edm Process Download Scientific Diagram

Pdf Literature Review On Electrical Discharge Machining Edm Vishal K Jaiswal Academia Edu

Electro Discharge Machining Edm Engineeringclicks

What Is Electrical Discharge Machining Edm Get It Made

:quality(80)/images.vogel.de/vogelonline/bdb/1877600/1877654/original.jpg)

What Is Electrical Discharge Machining And How Does It Work

Electrical Discharge Machining 101 Resources Fast Radius

What Is Wire Edm Electrical Discharge Machining Xact

Advantages Of Edm Machining For Aerospace Sans

What Is Electrical Discharge Machining Edm Get It Made

Electrical Discharge Machining Principles And Applications Rapiddirect

Beyond The Cnc What Is Electrical Discharge Machining Better Mro

Electric Discharge Machining Process Animation How Electric Discharge Maching Works Youtube

Wire Edm A Complete Guide To Wire Electric Discharge Machining Cncsourced